Materials for every market

Over the past few decades, plastic has become an integral part of many aspects of technology, efficiency, safety, and society.

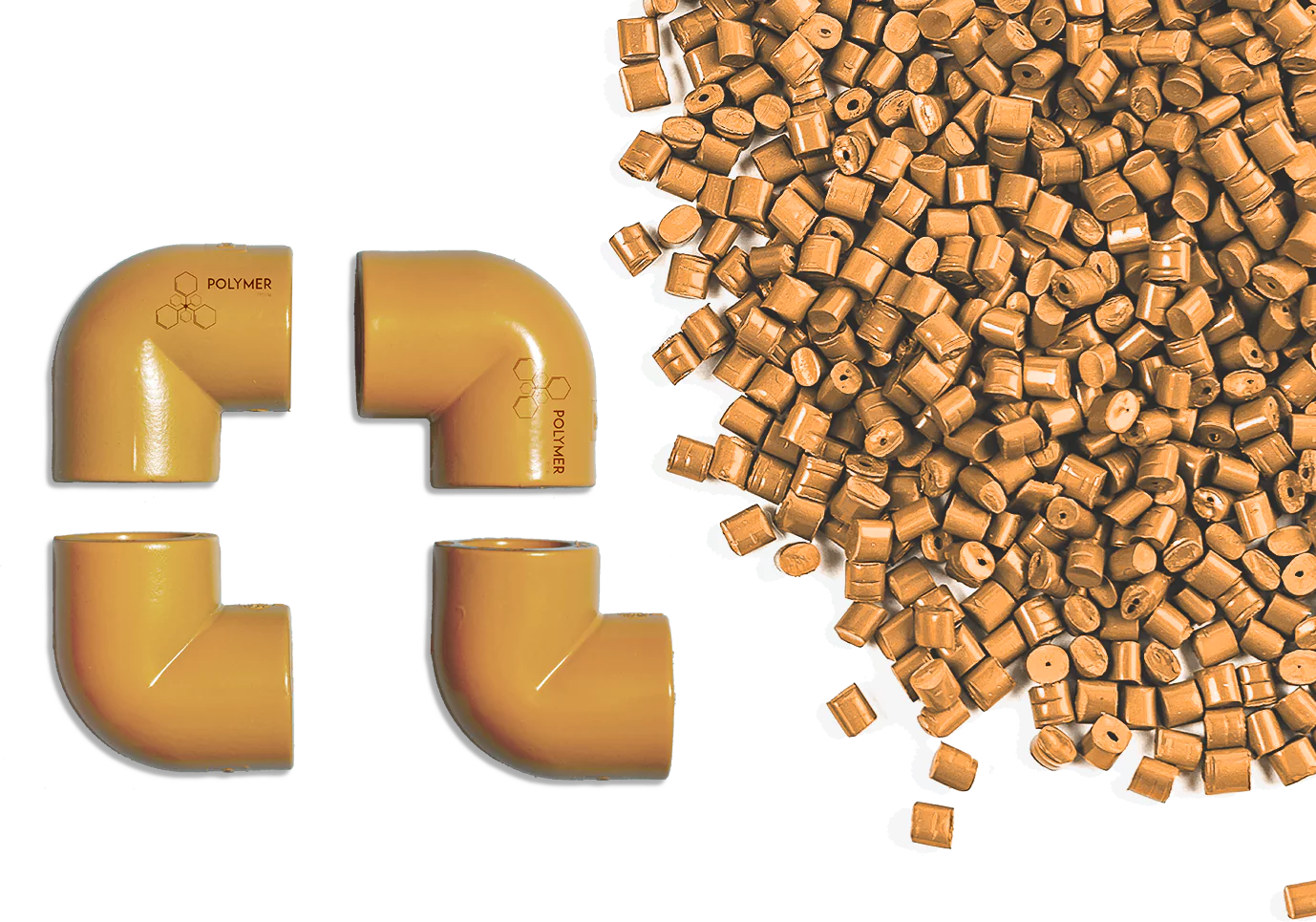

Hemp Plastic

We can adjust this formula to cater to your specific needs.

Free Call. Free Prototype. Free Molding. Free Mass Production.

INDUSTRIES AND APPLICATIONS

Our Products

Polymer Hemp aims to be a driving force in the bioplastics industry, contributing to its growth and the development of sustainable, eco-friendly materials

PolymerHemp

Biocomposites are blends of different materials used for their biocompatibility, superior mechanical properties, and biodegradability.

An organic “look of wood” communicates sustainability and practicality.

Hemp Fiber Biocomposite

Our environmentally friendly resin is ideal for high strength, low respiratory irritation and equipment wear. The renewable hemp fibers have low densities, low cost, high specific properties and their non-abrasive nature have both economic and environmental benefits in automotive, building, furniture and packaging industries.

Free Call. Free Prototype. Free Molding. Free Mass Production.

Environmentally Friendly

In recent years, the use of natural fibers as reinforcement materials has seen a significant rise. These fibers serve as strength and rigidity providers in composite materials, enhancing their overall performance. Notably, hemp-filled polypropylene has demonstrated substantial improvements in attributes such as tensile strength, flexibility, and impact resistance. At our company, we harness the maximum potential of these fibers in our compounds, ensuring superior quality and performance.