PolymerHemp

Biodegradable: Future Of Recycling

Firstly, hemp plastic is biodegradable, which means it can decompose naturally without harming the environment. This is a significant advantage over traditional plastics, which take hundreds of years to break down and release harmful chemicals into the soil and water. Biodegradable hemp plastic has received a lot of attention recently. What is hemp plastic, though, and what advantages does it have? A brand-new kind of recyclable plastic called hemp plastic is created by using the fiber and oil that have been extracted from the cannabis plant. Since hemp is a renewable

resource, hemp plastics are environmentally friendly and offer numerous advantages over conventional plastics.

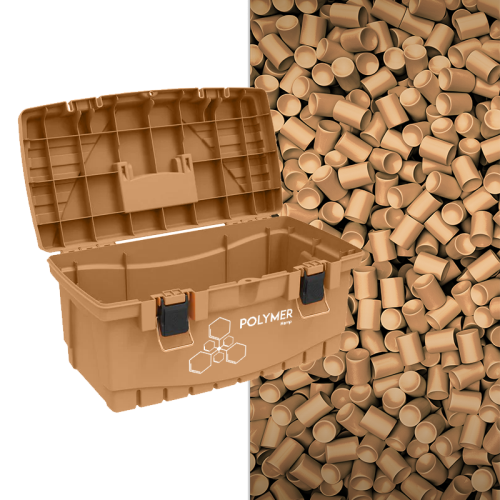

PLA-Hemp

Biodegradable

It is anticipated that biodegradable resins will help lessen the environmental issues brought on by synthetic resins. We created PLA-Hemp by blending 30–50 microns of hemp filler into Polylactic Acid (PLA), one of the more promising candidates. The PLA (polylactide)-based Polymerhemp 420 product is certified as a biodegradable resin and complies with ASTM D6400.

It contains about 30% hemp fiber filler. The toughness and processability have both significantly improved, making it simple to use in a molding or extrusion machine. a new, stronger additive created especially for packaging made of bio-based and biodegradable materials. method because it uses natural organisms to solve the issue, preserving the environment in a more natural state. This makes it an ideal choice for eco-friendly packaging solutions. Additionally, the use of biodegradable materials and natural organisms in the production process helps reduce the carbon footprint of the product.

Features

- Easy to handle.

- Provide excellent heat seak performance.

- Suitable for such food contact paper packages because.

- Composed of only biodegradable and safe materials.

Application

- Outstanding side sealing and end sealing performance.

- High-quality films for the automatic packing process.

- Blow molding for bottles.

- Translucent bags, bakery bags, envelope blogs.

- PLA is tougher

- High quality film for lamination.

- Hemp is the Future of plastics.

Free Call. Free Prototype. Free Molding. Free Mass Production

PLA-Hemp

It is anticipated that biodegradable resins will help lessen the environmental issues brought on by synthetic resins. We created PLA-Hemp by blending 30–50 micron hemp filler into Polylactic Acid (PLA), one of the promising candidates.

WHY Biodegradable?

The main characteristics include solvent-free, 100% compostable, solvent-free,biodegradable plastic, biopolymer, environmentally friendly coating, food and industrial paper packaging, contribution to the circular economy, reduction of waste problems, and heat-sealable agents. Specifically created for extrusion, extrusion grade is a thermoplastic resin made from yearly renewable resources.

Free Call. Free Prototype. Free Molding. Free Mass Production.

Why Bio-Plastic?

The same plant that produces traditional plastic is used to make hemp plastic, but a different kind of oil is used in its production. Hemp plastic is a good option for recycling because it is sustainable and biodegradable.

Free Call. Free Prototype. Free Molding. Free Mass Production.

HEMP PLASTIC

I developed our plastic formulation, which was later published in the esteemed journal Polymers from Renewable Resources, thanks to research at the University of Evansville and Kentucky’s extensive hemp fields. To create our plastic, we will follow this exact chemical engineering recipe. Exxon Mobil’s virgin copolymer resin, which has the highest integrity, serves as the base polymer. As a result, we can adjust the formulation to meet your needs.

Free Call. Free Prototype. Free Molding. Free Mass Production.

Friendly plastic

Hemp grows profusely after the fibers have been removed from the stems, making it a very effective crop for these environmentally friendly plastics known as “bioplastics.” The oil from hemp seeds is extracted to create hemp plastic. The oil is then transformed into plastic via a number of processes. Due to their strength and durability, hemp plastics are frequently used in the construction and automotive industries.

Basket

A novel type of recyclable material made from the cannabis plant is called hemp plastic. Hemp plastic is non-toxic and biodegradable, two benefits it has over conventional plastics. To become the recycling material of the future, hemp plastic must first overcome a few obstacles. The fact that hemp plastics are less durable than conventional plastics presents one difficulty.

They might not be durable enough to withstand misuse or repeated use, which might cause them to be thrown away rather than recycled. .

Sporting

Hemp is a completely biodegradable alternative to harmful, non-renewable plastics. In addition to being significantly more durable than plastic made from synthetic fibers or petroleum-based fibers, plant-based hemp fibers have no harmful toxins.

Henry Ford, the renowned automaker, was aware of these benefits

Baby

The most typical design for an aerosol container includes a shell, a valve, a “dip tube” that connects the valve to the liquid product, and a pressurized liquefied gas propellant.

честные казино с быстрыми выплатами

бездепозитные бонусы казино

играть в лучшем казино на деньги

база казино с бездепозитным бонусом

онлайн казино России

casino oyunu

Typically, the propellant is combined with the liquid product.

Waste Containers

Durable waste containers provide a dependable solution for waste management and reduction.